We use cookies on our website.

Some of them are necessary for the functioning of the site, but you can decide about others.

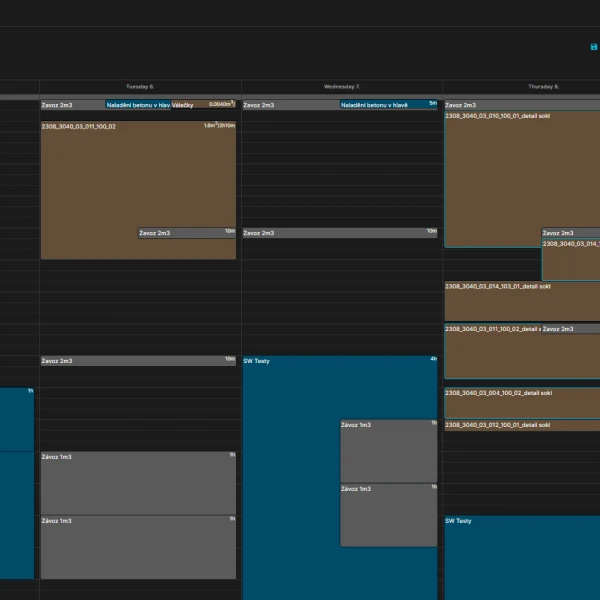

We have created our own comprehensive software for the preparation and management of printing data.

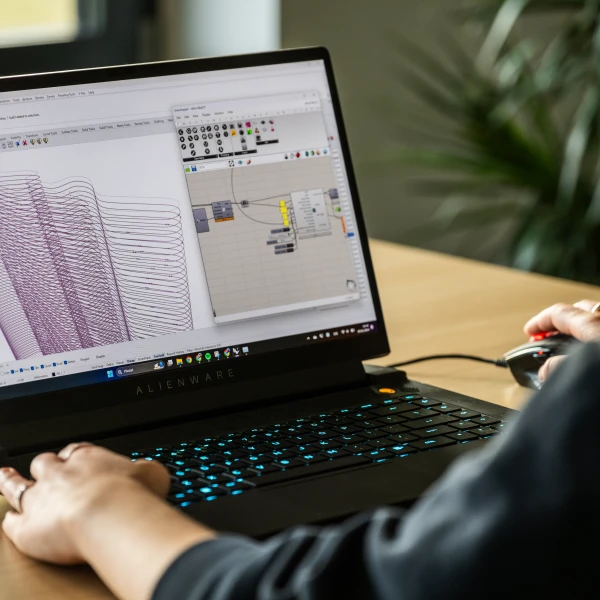

The software itself supports various design features such as tilting or changing layer properties.

Planning streamlines and optimizes the entire process, encompassing the functions of print and maintenance planning, along with calculating material consumption and optimizing its supplies.

Costing module helps to have detailed cost break downs for each printed object in few clicks.

These simulations help in identifying and mitigating problems such as collisions between the print head and the object, ensuring the print stays within the printing range, and optimizing the printing process for efficiency and accuracy.

The geometry of the design is sliced by the software into individual paths that guide the robot in printing each layer of concrete. The full digitization of the process is crucial in reducing labor and total costs.

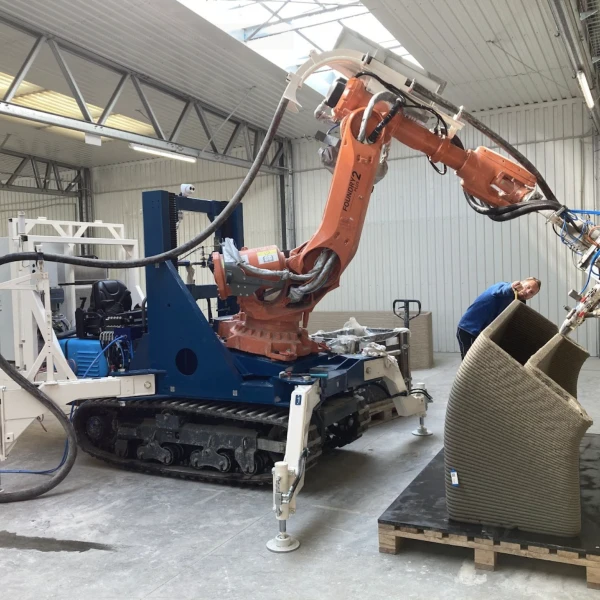

Changes in layer width can be achieved by adjusting the speed of the print head. This allows for efficient material distribution and significant cost savings.

Nonplanar printing allows for more complex geometries by enabling the printer to vary the orientation and angle of the printing nozzle or platform as it creates each layer. It can be used for compensating terrain irregularities or other special design needs.

Our system DatICE can collect, display and evaluate data in real time. Collected data are used for precision performance analytics.

For each print, a comprehensive history of print conditions and material properties is recorded. This allows for optimization of each subsequent print.

Learn more about our technology.